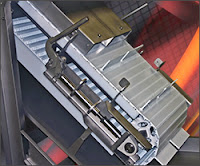

The NeXtconveyor Incline Conveyor with Infeed Hopper and Discharge Chute

Arrowhead Conveyor’s sanitary line of equipment NeXtconveyor, introduces a new and unique bulk hopper conveyor. Our latest design is this cleated incline conveyor with an infeed hopper and discharge chute. This system is capable of handling a wide variety of food or pharmaceutical products. Our NeXtgen hybrid design is suitable for USDA applications such as raw meats, poultry and seafood.

Cleated Belt Design

|

| Infeed Hopper |

|

| Three Pin Bracket |

Three Pin Bracket

This NeXtgen hybrid features the latest in sanitary design from our engineers. The three pin bracket seat design for the underneath drip pans allows for quick and easy disassembly for cleaning.

Roller Uptake

|

| Roller Uptake |

A front cover plate finishes off the sanitary design to ensure products stay contaminate free and also offers the benefit of easy fastener-free removal for clean up duty.